In Today’s world, food preservation is more important than ever before, Historically there were many Methods of food preservation, like drying, smoking, pickling, salting etc.. These rather primitive methods are still widely used today, not only in backward societies, where no other means are available, but also in modern societies where they serve to supplement the more modern methods of food preservation like refrigeration.

In the Individual Quick Freezing (IQF) process, unlike other freezing processes, the products are frozen as individual pieces. This offers greater convenience to the consumers and hence adds more value to the product. The IQF process is far superior to the conventional processes. In Quick freezing, small ice crystals forms within the product thus its own fresh quality is maintained even after extended shelf life. Most foods can be preserved for a long time if they are frozen quickly and kept at a low temperature until ready for use. Slow, natural freezing destroys food because the low temperatures draw all the water from the tiny cells of the food, affecting color and flavour.

Quick freezing method prevents breakage of the cell walls as the freezing process is so quick. Thus, in quick-frozen food most of the flavour, colour and firmness are retained.

Application of Individual Quick freezing (IQF):

- Fruit & vegetables processing

- Meat & fish Processing

- Ready to eat products

- Other Cooked Food items

Features of Rinac’s FREEZOLINE IQF:

Rinac offers IQF freezer unit along with matching refrigeration packages,[ liquid over feed type ] all are ready to install at the site.

- Modules of capacity ranging from 250 to 3000 kg/hr.

- Enclosure made of energy efficient sandwich panels with RPUF core and stainless steel /per-painted GI metal lamination inside and outside respectively.

- Stainless steel finish floor with built in drain system.

- Single or multiple belt unit of SS/ PE / POE.

- High static fans for excellent fluidization.

- Variable speed drive with motor control VFD

- Varying fin type Cooling coil of SS tubes/aluminum fins suitable for ammonia liquid pumping.

- PLC based control panel with Touch screen and product based operation modes.

- Automatic Air defrost system [for Straight line IQF] with unique FROST BUSTER.

Nomenclature of FREEZOLINE Freezer

| FREEZOLINE | FST | 05 | ||

|---|---|---|---|---|

| FSP | ||||

| FTF | ||||

| FPF | ||||

| FBF[S/X] | ||||

| RINAC Individual Quick Freezer | ||||

| Straight Line IQF – FST, Spiral Freezer – FSP, Tunnel Freezer -FTF, Plate Freezer – FPF, Blast Freezer – FBF[Soft blast -S, Hard blast X] | ||||

| Throughput in kg/hr – Digit x 100 |

Note : Soft Blast used for upto 40mm thk fish/meat & Hard Blast used for above 40mm thk

FREEZOLINE Technical Description:

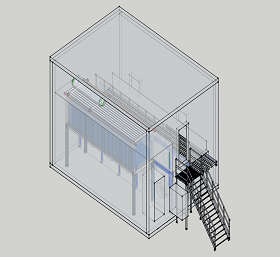

Rinac’s IQF freezer is completely pre-fabricated, factory tested prior to shipping. The conveyor made of continuous belt, MOC either SS / PE / POE. The conveyor supports are made of Aluminum lined, low friction, food grade, plastic wear strips[UHMPV] designed for minimum belt wear. The enclosure of the chamber is constructed with rigid polyurethane insulation, of 150mm thick Wall & ceiling, 200mm thick for floor along with entry/inspection doors, walk ways with in the chamber along with stairs, located at critical locations for easy inspection, cleaning, and maintenance. The freezer is built to food grade standards.

Cooling coil will be of SS/Al construction with varying fin configuration for enhanced performances. The frigid air is delivered by high-efficiency aero-foil construction fan impeller which is directly driven by high efficiency motors. Both Straight and spiral units are equipped with water defrosting arrangement for coil. The straight line IQFs will have an automatic, advance Air Defrost technology[ADF] system for a longer operation period, between defrost intervals. The floor shall be of SS Finish with built in Clean Flow drainage systems. In feed conveyor is covered with insulated boxing & outlet feed with product collection tray. The straight line IQF units will have an infeed shaker unit at the product entry point.

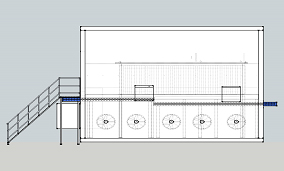

FREEZOLINE FST Straight belt IQF Freezer

General Information:

Our FREEZOLINE Straight IQF delivers maximum uptime, exceeds your hygiene needs, and make your processing easy and power efficient. It will meet your processing needs & Increases your processing potential, exactly, at the same time it gives you freedom and flexibility to grow your business in the most cost-effective way.

Our FREEZOLINE series Individual Quick Freezer Skid Package Unit Comprise of Suitable Capacity Cooling Coils, Vane Axial Fans, Motors, SS/PE belt Conveyor, Pre-Engineered and Pre-Fabricated enclosure of RPUF Panels.

Airflow designs are optimized to match the physical and thermal properties of the product, to provide fast, uniform freezing combined with economical in operation.

The structure design and material selection results in lower maintenance requirements, longer component life and reduced downtime.

Benefits of FREEZOLINE FST IQF

The IQF freezing uses a bed of supercooled air to suspend and separate solid food products, simultaneously freezing them. Our IQF Conveyor design optimized for directing air evenly towards the product and ensures better quality crust freezing by locking the product moisture before the final core freezing, as well as preserving product weight, appearance and quality. Product Agitator in the pre-cooling section provided to avoid lumping of product.

- The appeal of IQF frozen fruits and vegetables are near to the much-sought-after appearance, flavour and nutrition as of fresh ones.

- Individually quick frozen products lock in the essential nutrients and flavour, with optimum colour, taste and texture.

- The IQF process makes it possible to offer ’fresh picked’ flavours all year round, in packaging convenient for today’s busy consumer.

- Two-Stage fluidization System Gives Optimum Freezing Process: The crust freezing zone (belt 1) and the deep freezing zone (belt 2).

- Factory Finished SS Floor with built in Drain arrangement.

- Automatic air defrost system. Air Defrost system ensure beyond 18 hours of continuous operation without water defrost.

- The electrical Control Panel includes extreme user friendly PLC touch screen control panel, emergency stop system along with VFDs and UPS control power.

- Individually adjustable double Belt system for different product processing.

- High velocity airflow inside freezers ensures high quality of freezing. The air flow is controlled to perfectly suit each product which gives an even temperature throughout the freezer and uniform high product quality.

- Operate as complete standalone or option to operate in combination with other systems.

Straight line IQF units are equipped with automatic Air Defrost system, especially for processing vegetable & fruit products which carry high water percentage. The continuous removal of frost considerably extends the effective operation time and efficiency of freezing thus extending the time intervals between the defrost hence increasing the total daily production capacity over 25-30 %. Air Defrost system runs automatic with help of PLC based control system. The continuous air jet will remove frost from coil and prevent frost built-up during working, which results better air flow through coil and enhanced heat transfer.

| Sl. No | Skid nomenclature | Throughput in kg/hr [ Based on Peas] |

|---|---|---|

| 1 | FREEZOLINEFST05 | 500 |

| 2 | FREEZOLINEFST10 | 1000 |

| 3 | FREEZOLINEFST20 | 2000 |

| 4 | FREEZOLINEFST25 | 2500 |

| 5 | FREEZOLINEFST30 | 3000 |

| Sl. No. | Description | UOM | FST 500 | FST 1000 | FST 2000 | FST 2500 | FST 3000 |

|---|---|---|---|---|---|---|---|

| General Details | |||||||

| 1 | Nominal Capacity | kg/Hr | 500 | 1000 | 2000 | 2500 | 3000 |

| 2 | Capacity to be based on | Green Peas | Green Peas | Green Peas | Green Peas | Green Peas | |

| 3 | Room Size | ||||||

| a | Length | m | 4.0 | 6.0 | 7.6 | 9.3 | 11.0 |

| b | Width | m | 4.0 | 4.0 | 5.0 | 5.0 | 5.0 |

| c | Height | m | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 |

| 4 | Design Ambient Temp. | Deg C | 42 | 42 | 42 | 42 | 42 |

| 5 | Incoming Temp. of Product | Deg C | 10-12 | 10-12 | 10-12 | 10-12 | 10-12 |

| 6 | Outgoing temp. of Product | Deg C | -18 | -18 | -18 | -18 | -18 |

| Panel Details | |||||||

| 1 | Wall / Ceiling / Floor Insulation | Type | RPUF | RPUF | RPUF | RPUF | RPUF |

| 2 | Insulation Density | Kg/m3 | 38 +/- 2 | 38 +/- 2 | 38 +/- 2 | 38 +/- 2 | 38 +/- 2 |

| 3 | Thermal Insulation U value | W/m2.K | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 |

| 4 | Wall Insulation Thickness | mm | 150 | 150 | 150 | 150 | 150 |

| 5 | Ceiling Insulation Thickness | mm | 150 | 150 | 150 | 150 | 150 |

| 6 | Floor Insulation Thickness | mm | 200 | 200 | 200 | 200 | 200 |

| 7 | Floor Finish | SS | SS | SS | SS | SS | |

| Belt Details | |||||||

| 1 | Width of Belt | mm | 750 | 900 | 1200 | 1200 | 1200 |

| 2 | Type of Belt | PE/POE/SS | PE/POE/SS | PE/POE/SS | PE/POE/SS | PE/POE/SS | |

| 3 | Effective belt area inside | m2 | 2.7 | 5.1 | 8.7 | 10.8 | 12.8 |

| 4 | Holding Time | min | 10 to 5 | 10 to 5 | 10 to 5 | 10 to 5 | 10 to 5 |

| Refrigeration Details | |||||||

| 1 | Base Load | TR | 8 | 13 | 19 | 24 | 28 |

| 2 | Power consumption for IQF | kW | 21 | 32 | 50 | 63 | 75 |

| 3 | Power Connected for IQF | kW | 26 | 40 | 63 | 78 | 93 |

| 4 | Type of Defrost | ADF + WDF | ADF + WDF | ADF + WDF | ADF + WDF | ADF + WDF | |

| 5 | Type of speed control of conveyor | VFD | VFD | VFD | VFD | VFD | |

| 6 | MOC of the cooling coil | SS/Al | SS/Al | SS/Al | SS/Al | SS/Al | |

| 7 | Supply Main | 3Ph 415V 50Hz | 3Ph 415V 50Hz | 3Ph 415V 50Hz | 3Ph 415V 50Hz | 3Ph 415V 50Hz | |

| 8 | Refrigerant | NH3[R717] | NH3[R717] | NH3[R717] | NH3[R717] | NH3[R717] | |

| 9 | Total Required Refrigeration Capacity @ -40 SST | TR | 18 | 38 | 76 | 100 | 120 |

| Sl. No. | Product Name | Size of the product taken [mm] | Density | Freezing time | FSF05 | FSF10 | FSF20 | FSF25 | FSF30 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| L | B | H | kg/m3 | mins | kg/hr | kg/hr | kg/hr | kg/hr | kg/hr | ||

| VEGETABLES | |||||||||||

| 1 | Pea | 8 | 8 | 8 | 705 | 4.3 | 500 | 1000 | 2000 | 2500 | 3000 |

| 2 | Beans | 30 | 10 | 10 | 689 | 7.3 | 290 | 580 | 1160 | 1450 | 1740 |

| 3 | Broccoli | 15 | 15 | 15 | 561 | 7.3 | 240 | 480 | 960 | 1200 | 1440 |

| 4 | Carrot | 25 | 25 | 5 | 593 | 6.1 | 300 | 600 | 1200 | 1500 | 1800 |

| 5 | Cauliflower | 15 | 15 | 15 | 593 | 7.5 | 250 | 500 | 1000 | 1250 | 1500 |

| 6 | Corn | 10 | 10 | 10 | 625 | 4.9 | 410 | 820 | 1640 | 2050 | 2460 |

| 7 | Okra | 20 | 20 | 15 | 593 | 7.3 | 250 | 500 | 1000 | 1250 | 1500 |

| 8 | Potatoes | 10 | 8 | 8 | 609 | 5.7 | 330 | 660 | 1320 | 1650 | 1980 |

| FRUITS | |||||||||||

| 1 | Apple fresh | 20 | 15 | 10 | 865 | 7.9 | 280 | 560 | 1120 | 1400 | 1680 |

| 2 | Sweet cherry | 15 | 15 | 15 | 625 | 7.4 | 230 | 460 | 920 | 1150 | 1380 |

| 3 | Mangoes | 15 | 15 | 15 | 641 | 7.5 | 220 | 440 | 880 | 1100 | 1300 |

| 4 | Pineapple | 20 | 20 | 15 | 625 | 9.3 | 220 | 440 | 880 | 1100 | 1300 |

| 5 | Strawberries | 30 | 20 | 8 | 817 | 7.2 | 250 | 500 | 1000 | 1250 | 1500 |

Rinac’s FREEZOLINE spiral freezers come with externally located direct drive system for drum & over drive. The drum speed and the conveyor belt speed can be varied through a variable frequency drive depending on products. The supporting structure on the outside, drum and the linear sections of the conveyor etc. are fabricated with SS-304 material. The dwell time inside the freezer can be varied from 30 minutes to 60 minutes.

PE / POE belts are designed to match your specific product and production requirements. The conveyor supports are constructed with suitable low temperature, low friction, food grade plastic, wear strips[UHMPV] designed for a minimum belt wear, provided for the belt support and on the linear section.

By ensuring a controlled uniform airflow, it optimizes quality and minimizes dehydration. The refrigeration coils are constructed from SS/CU/AL tubes and Al fins, designed for maximum heat-transfer efficiency.

Fans directly driven by high efficiency motors with optimized air velocity through evaporator, Increased production uptime, greater freezing capacity, increased reliability, maximum heat transfer with the lowest possible energy consumption.

Fully seal-welded, stainless steel floor design for faster cleaning with in built drainage system ensures Improved hygiene. With high-efficiency rigid polyurethane insulation, the base load is Optimized to minimum. Access doors are located at critical positions for easy inspection, cleaning, and maintenance.

The spiral freezer is also provided with LED lights, Panic alarm, door, door frame, drain tray and drain heaters. The Spiral freezer is provided with PLC based control system for an efficient equipment operation. Will have additional feature of Special camera with product view/ display system for monitoring product movement remotely.

- Factory Finished SS Floor with built in Drain arrangement.

- The electrical Control Panel includes extreme user friendly PLC touch screen control panel, emergency stop system together with lighting control, located outside the freezer.

- Adjustable Belt speed through frequency controlled motors in order to adjust holding times.

- Designed for continuous production

- High velocity airflow inside freezers ensures high quality of freezing

- Food grade MOC gives high standard of hygiene

- In built stainless steel deflectors helps to direct cold air over product

- Can be used as a complete standalone or in combination with other systems.

| Sl. No | Skid nomenclature | Throughput in kg/hr |

|---|---|---|

| 1 | FREEZOLINEFSP 03 | 250 |

| 2 | FREEZOLINE FSP05 | 500 |

| 3 | FREEZOLINE FSP10 | 1000 |

| Sl. No. | Description | UOM | FSP03 | FSP05 | FSP10 |

|---|---|---|---|---|---|

| General Details | |||||

| 1 | Nominal Capacity | kg/Hr | 250 | 500 | 1000 |

| 2 | Capacity to be based on | Ready To eat Items | Ready To eat Items | Ready To eat Items | |

| 3 | Room Size | ||||

| a] Length | m | 6 | 6.5 | 10 | |

| b] Width | m | 5.4 | 5.4 | 6.5 | |

| c] Height | m | 3 | 4.2 | 4.2 | |

| 4 | Design Ambient Temp. | Deg C | 42 | 42 | 42 |

| 5 | Incoming Temp. of Product | Deg C | 60 | 60 | 60 |

| 6 | Outgoing temp of Product | Deg C | -18 | -18 | -18 |

| Panel Details | |||||

| 1 | Wall / Ceiling / Floor Insulation | Type | RPUF | RPUF | RPUF |

| 2 | Thermal Insulation Density | Kg/m3 | 38 +/- 2 | 38 +/- 2 | 38 +/- 2 |

| 3 | Thermal Insulation U value | W/m2.K | 0.13 | 0.13 | 0.13 |

| 4 | Wall Insulation Thickness | mm | 150 | 150 | 150 |

| 5 | Ceiling Insulation Thickness | mm | 150 | 150 | 150 |

| 6 | Floor Insulation Thickness | mm | 200 | 200 | 200 |

| Belt Details | |||||

| 1 | Tier Clearance | mm | 120 | 100 | 100 |

| 2 | Number of Tiers | 8 | 16 | 16 x 2 | |

| 3 | Width of Belt | mm | 500 | 500 | 500 |

| 4 | Type of Belt | PE | PE | PE | |

| 5 | Length per tier | m | 10 | 10 | 10 |

| 6 | Effective belt area per tier | m2 | 5 | 5 | 5 |

| 7 | Holding Time | min | 60 to 30 | 60 to 30 | 60 to 30 |

| Refrigeration Details | |||||

| 1 | Base Load | TR | 4 | 7 | 12 |

| 2 | Power consumption for IQF | kW | 6.4 | 10 | 20 |

| 3 | Power Connected Data for IQF | kW | 8 | 13 | 26 |

| 4 | Type of Defrost | Water Defrost | Water Defrost | Water Defrost | |

| 5 | Type of speed control of conveyor | VFD | VFD | VFD | |

| 6 | MOC of the cooling coil | SS | SS | SS | |

| 7 | Supply Main | 3Ph 415V 50Hz | 3Ph 415V 50Hz | 3Ph 415V 50Hz | |

| 8 | Refrigerant | NH3[R717] | NH3[R717] | NH3[R717] | |

| 9 | Total Required Refrigeration Capacity @ -40 SST | TR | 18 | 27 | 52 |

| Sl. No. | Product Name | Size of the product taken | Weight | Freezing Time | Product Processing Rate | ||||

|---|---|---|---|---|---|---|---|---|---|

| L [mm] | B [mm] | H [mm] | grams | min | FSP03 | FSP05 | FSP10 | ||

| 1 | Idli | 90 | 90 | 12 | 50 | 40 | 220 | 440 | 880 |

| 2 | Vada | 100 | 100 | 20 | 30 | 30 | 210 | 420 | 840 |

| 3 | Samosa | 76 | 76 | 23 | 50 | 45 | 250 | 500 | 1000 |

| 4 | Chapthi/Tortila | 125 | 125 | 6 | 40 | 30 | 280 | 560 | 1120 |

| 5 | Parota | 125 | 125 | 10 | 90 | 30 | 260 | 520 | 1040 |

| 6 | Cup ice-cream | 100 | 100 | 40 | 100 | 60 | 230 | 460 | 920 |

| 7 | Pizza base | 200 | 200 | 10 | 150 | 90 | 220 | 440 | 880 |

| 8 | Bun | 80 | 80 | 30 | 60 | 60 | 300 | 600 | 1200 |